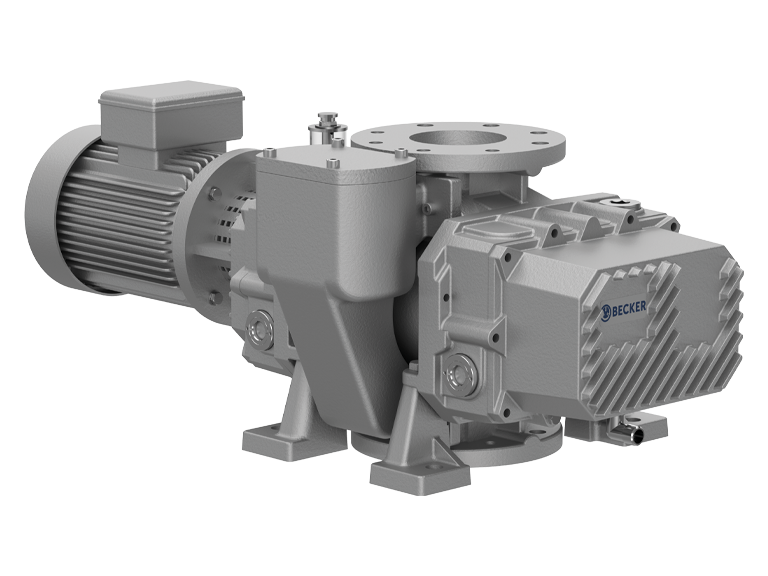

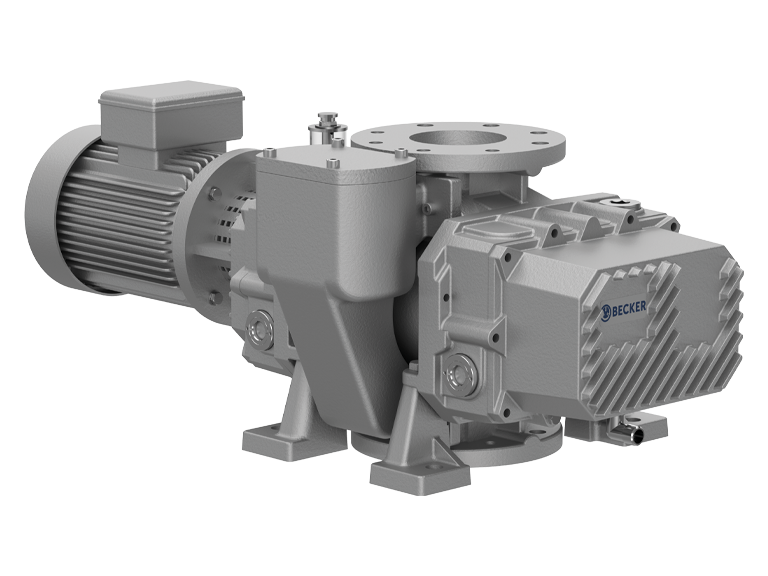

Product Description

Product Description

Roots blower is a volumetric blower, also called a rotary blower, which is a mechanical device used to transport gas. It consists of 2 intermeshing rotors that rotate to generate airflow and compress and discharge the gas. Roots blowers are usually used in air boosting, vacuum pumps, pneumatic conveying, water treatment, dust recovery, pneumatic conveying, power plant desulfurization, paint spraying and other industries.

Working Principle

It is mainly composed of casing, wall panel, impeller, fuel tank and muffler. The casing plays a supporting and fixing role, and the wall plate is used to connect the casing and the impeller, support the rotation of the impeller, and also has the effect of end face sealing. The impeller is the rotating part of the Roots blower, usually composed of 2 or 3 blades. Compared with 2 blades, the three-bladed rotor has the advantages of smaller air pulsation, lower noise and smoother operation. The oil tank is used to store lubricating oil used to lubricate gears and bearings, while the muffler is used to reduce the noise caused by air pulsation when the Roots blower enters and exits.

Advantages

Application

Product Parameters

| WSR Dense Type Roots Blower Model | Caliber | A | B | C | D | E | F | G | H | J | K | L | M | N | O | X | R | V | n-d | Weight(kg) |

| WSR-50MJ | 50A | 380 | 90 | 105 | 120 | 19 | 450 | 240 | 578 | 450 | 970 | 125 | 320 | 200 | 560 | 185 | 90 | 100 | 18 | 100 |

| WSR-65MJ | 65A | 450 | 100 | 115 | 130 | 19 | 480 | 240 | 615 | 500 | 1050 | 140 | 360 | 240 | 650 | 205 | 90 | 100 | 18 | 110 |

| WSR-80MJ | 80A | 500 | 110 | 135 | 140 | 19 | 500 | 250 | 680 | 530 | 1150 | 150 | 380 | 260 | 700 | 220 | 90 | 100 | 18 | 150 |

| WSR-100MJ | 100A | 540 | 110 | 150 | 140 | 19 | 520 | 265 | 707 | 600 | 1200 | 200 | 490 | 370 | 780 | 260 | 90 | 100 | 18 | 180 |

| WSR-125MJ | 125A | 600 | 120 | 165 | 150 | 21 | 560 | 280 | 777 | 710 | 1380 | 215 | 490 | 370 | 860 | 295 | 90 | 120 | 18 | 280 |

| WSR-150MJ | 150A | 760 | 130 | 180 | 150 | 24 | 620 | 340 | 881 | 860 | 1565 | 250 | 610 | 470 | 1060 | 375 | 100 | 120 | 18 | 430 |

| WSR-175MJ | 175A | 850 | 130 | 180 | 150 | 24 | 620 | 340 | 881 | 960 | 1565 | 320 | 720 | 580 | 1150 | 470 | 100 | 120 | 18 | 680 |

| WSR-200WJ | 200A | 1050 | 150 | 190 | 160 | 29 | 750 | 380 | 1095 | 1080 | 1920 | 304 | 775 | 640 | 1400 | 525 | 100 | 140 | 18 | 980 |

| WSR-250MJ | 250A | 1340 | 160 | 230 | 250 | 30 | 900 | 400 | 1320 | 1258 | 2300 | 460 | 970 | 800 | 1900 | 608 | 140 | 180 | 26 | 1858 |

| WSR-300WJ | 300A | 1340 | 160 | 245 | 250 | 40 | 950 | 420 | 1460 | 1433 | 2480 | 375 | 970 | 800 | 1900 | 756 | 140 | 180 | 26 | 2356 |

Company Profile

HangZhou Oyang Machinery Equipment Co.,Ltd is located in HangZhou City,ZheJiang Province.

Our factory is established in HangZhou city since 2012, with workshop area is 20,000 square CHINAMFG and rich experience in sewage treatment.

We have long term relationships with mobile cabin hospital,Railway group,State grid,CRCC,and so on.

The company’s main products: integrated sewage treatment equipment, domestic sewage treatment equipment, buried sewage treatment equipment, air flotation machine, industrial sewage treatment equipment, belt filter press, sludge dewatering machine, vacuum filter, rural sewage treatment equipment , Hospital sewage treatment equipment, slaughter sewage treatment equipment, coal mine sewage treatment equipment and other environmental protection equipment.

Products are widely used in domestic industrial and mining enterprises, living quarters, urban and rural areas, food, petrochemical, papermaking, breeding and slaughtering, leather, textile, printing and dyeing, hospitals, hotels and other fields.

Corner of workshop

Certifications

FAQ

Q: Are you trading company or manufacturer?

A: We are factory. We are professional manufacturer which specializes in producing waste water treatment equipments.

Q: Where is your factory located?

A: HangZhou City, ZheJiang Province.

Q: Do you provide OEM service?

A: Yes. Any required logos are available.

Q: How could we trust you and your company? This is first time transaction?

A: Our company has long term professional experience. We cooperate over 1000 customers in China and overseas. We export nearly 50 countries all over the world. Welcome to our company and visit our plant production condition any time.

Q: Do you offer after-sales service?

A: Yes. Engineers available for technology assistence.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Service |

|---|---|

| Warranty: | 1 Year |

| Service Life: | 10-30 Years |

| Samples: |

US$ 2000/Piece

1 Piece(Min.Order) | Order Sample customized color

|

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can Roots Vacuum Pumps Be Used for Vacuum Impregnation in Manufacturing?

Yes, Roots vacuum pumps can be used for vacuum impregnation in manufacturing. Here’s a detailed explanation:

1. Vacuum Impregnation in Manufacturing: Vacuum impregnation is a process used in manufacturing to fill porous materials or components with a liquid or resin. It is commonly employed to enhance the properties of materials by improving their strength, sealing capability, or resistance to chemicals or corrosion. The process involves placing the porous material in a vacuum chamber and removing the air or gas trapped within its pores. Once a vacuum is established, a liquid or resin is introduced, and the vacuum is released, allowing the material to absorb the impregnating substance.

2. Role of Roots Vacuum Pumps: Roots vacuum pumps play a crucial role in the vacuum impregnation process by creating and maintaining the required vacuum conditions. Here’s how they contribute:

– Evacuation: Roots pumps are used to evacuate the impregnation chamber, removing the air and gas from within the pores of the porous material. By creating a vacuum, the trapped gases are extracted, creating a void space for the impregnating substance to penetrate.

– Pressure Control: Roots pumps help control the pressure within the impregnation chamber during different stages of the process. They can rapidly achieve and maintain the desired vacuum level, ensuring proper impregnation of the material and preventing the formation of air bubbles or voids.

– Gas Removal: Roots pumps effectively remove gases released from the impregnating substance during the impregnation process. As the liquid or resin fills the pores of the porous material, gases may be released due to the reaction or outgassing. The vacuum pump evacuates these gases, preventing their accumulation and ensuring complete impregnation.

3. Advantages of Roots Vacuum Pumps for Vacuum Impregnation:

– High Pumping Speed: Roots vacuum pumps have a high pumping speed, enabling rapid evacuation of the impregnation chamber. This reduces the overall impregnation cycle time, increasing manufacturing throughput and efficiency.

– Large Volume Handling: Roots pumps are capable of handling large volumes of gas, allowing them to evacuate chambers of different sizes effectively. This is advantageous when impregnating large or complex-shaped components that require a significant amount of impregnating substance.

– Continuous Operation: Roots pumps can operate continuously, maintaining the vacuum conditions required for impregnation throughout the process. This ensures consistent impregnation results and reduces the risk of incomplete impregnation or material defects.

– Compatibility with Impregnating Substances: Roots vacuum pumps are compatible with a wide range of impregnating substances, including resins, oils, solvents, and other liquids. They can handle different chemical compositions and provide a clean and efficient environment for the impregnation process.

4. Considerations for Vacuum Impregnation:

– Material Compatibility: It is essential to consider the compatibility of the porous material with the impregnating substance and the impregnation process itself. Some materials may require pre-treatment or surface preparation before impregnation. The choice of impregnating substance should also align with the material’s properties and intended application.

– Process Parameters: Vacuum impregnation involves controlling various process parameters, such as vacuum level, impregnation time, pressure release, and curing conditions. These parameters may vary depending on the material, impregnating substance, and desired impregnation results. Proper process optimization and control are crucial for achieving consistent and reliable impregnation outcomes.

– System Design: The design of the vacuum impregnation system should consider factors such as chamber size, gas flow rates, vacuum pump capacity, and pressure control mechanisms. Proper system design ensures efficient operation, reliable vacuum conditions, and effective impregnation of the porous material.

In summary, Roots vacuum pumps are well-suited for vacuum impregnation in manufacturing. Their high pumping speed, large volume handling capability, continuous operation, and compatibility with impregnating substances make them effective in creating and maintaining the required vacuum conditions for successful impregnation. By considering material compatibility, process parameters, and system design, Roots vacuum pumps contribute to the efficient and reliable impregnation of porous materials in various manufacturing applications.

Can Roots Vacuum Pumps Be Used for Vacuum Distillation?

Yes, Roots vacuum pumps can be used for vacuum distillation in certain applications. Here’s a detailed explanation:

Vacuum distillation is a process used to separate and purify components of a liquid mixture by exploiting the difference in boiling points under reduced pressure. By operating at lower pressures, the boiling points of the components are decreased, allowing for more selective evaporation and separation. Vacuum distillation is commonly employed in industries such as petrochemical, pharmaceutical, and chemical manufacturing.

Roots vacuum pumps can play a role in vacuum distillation processes by assisting in the creation and maintenance of the required vacuum conditions. Although Roots vacuum pumps alone may not achieve the high vacuum levels necessary for certain applications, they are often used in combination with other vacuum pumps, such as rotary vane pumps or oil-sealed pumps, to create a hybrid pumping system.

In a typical setup, Roots vacuum pumps are utilized as the primary roughing pump in the distillation system. Their high pumping speed allows for efficient removal of large volumes of gas, reducing the pressure in the system and enabling the effective operation of subsequent stages. The Roots pump works by trapping and compressing the gas, creating a pressure differential that facilitates the evacuation of the system.

While Roots vacuum pumps are effective in generating rough vacuum levels, they may not be capable of achieving the very high vacuum levels often required for precise separation in vacuum distillation. Therefore, they are commonly used in conjunction with other vacuum pumps, such as oil-sealed pumps or molecular pumps, that are better suited for achieving and maintaining high vacuum levels.

It’s important to note that the selection and configuration of the vacuum pumps for vacuum distillation depend on various factors, including the desired vacuum level, the characteristics of the liquid mixture being distilled, and the specific requirements of the distillation process. The vacuum system needs to be carefully designed to ensure optimal performance and efficient separation.

In summary, while Roots vacuum pumps alone may not be sufficient for achieving the high vacuum levels required for vacuum distillation, they are commonly employed as part of a hybrid pumping system in conjunction with other vacuum pumps. Their high pumping speed and capability to handle large gas volumes make them valuable for creating the initial vacuum conditions in the distillation process.

editor by Dream 2024-04-25