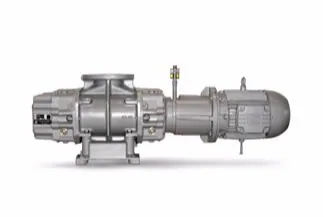

Product Description

Product Description

Roots pump is a kind of vacuum pump without internal compression. It is a vacuum pump that realizes air extraction by moving gas under the pushing action of synchronous and reverse rotation of a pair of “8” shaped rotors in the pump cavity. Generally, the pumping rate is large and the power of the motor is small, so the front pump is required to pre pump. After the front pump reaches the specified vacuum degree, start the roots vacuum pump to improve the pumping speed and vacuum degree. Its structure and working principle are similar to roots blower. During operation, its suction is connected with the evacuated container or the main pump of vacuum system. There is no contact between rotors of Roots vacuum pump and between rotors and pump casing.

Our Advantages

The running parts in the pump have no friction, no lubrication, and there is no oil in the pump cavity, so a clean vacuum can be obtained.

2 leaf involute cycloid profile, high-precision machining to ensure smooth and quiet operation.

the gas in the pump chamber flows vertically, which is conducive to the discharge of dust and condensate in the pumped gas.

. The high-strength rotor with complete symmetry and precise dynamic balance operates stably and reliably.

high precision gear, imported bearing, low vibration and noise.

the new omni-directional three-dimensional water-cooling jacket design can effectively cool the pump body and greatly prolong the service life of the pump.

the overflow surface can be plated with shackles, Hastelloy and PTFE, which can adapt to corrosive environments with different strengths.

it is convenient to form roots vacuum unit with liquid ring vacuum pump, rotary vane vacuum pump and dry vacuum pump.

Typical Use

——Oil and gas recovery. ——Biological medicine ——Food Processing —— Single crystal furnace

——Vacuum forming ——Vacuum flame refining ——Electronic photovoltaic. ——Semiconductor synthesis

Product Parameters

| Type | Pumping Speed L/S | Maximum allowable differential pressure (Pa) | Pump Speed(RPM) | Inlet Diameter(mm) | Outlet Diameter(mm) | Motor Power(kw) |

| ZJB-70 | 70 | 8000 | 2850 | 80 | 50 | 1.5 |

| ZJB-150 | 150 | 6000 | 2850 | 100 | 80 | 3 |

| ZJB-300 | 300 | 5000 | 2900 | 150 | 100 | 4 |

| ZJB-600 | 600 | 4000 | 2900 | 200 | 150 | 5.5Z7.5 |

| ZJ-1200 | 1200 | 3000 | 2900 | 250 | 200 | 11/15 |

| ZJ-2500 | 2500 | 2600 | 2900 | 300 | 250 | 22 |

| ZJ-3750 | 3750 | 2600 | 1450 | 350 | 350 | 30 |

| ZJ-5000 | 5000 | 2600 | 1450 | 400 | 400 | 45 |

Detailed Photos

General Manager Speech

Deeply cultivate the vacuum technology, and research,develop and manufacture the vacuum equipment to provide the best solution in the vacuum field and make the vacuum application easier.

Company Profile

ZheJiang Kaien Vacuum Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and operation of vacuum equipment. The company has strong technical force, excellent equipment and considerate after-sales service. The product manufacturing process is managed in strict accordance with IS09001 quality system. It mainly produces and sells screw vacuum pump, roots pump, claw vacuum pump, runoff vacuum pump, scroll pump, water ring vacuum pump, vacuum unit and other vacuum systems.

New plant plHangZhou

The company’s products have been for a number of food, medicine, refrigeration, drying plants and a number of transformer related equipment manufacturers for vacuum equipment. The products are widely used in vacuum drying and dehydration, kerosene vapor phase drying, vacuum impregnation, vacuum metallurgy, vacuum coating, vacuum evaporation, vacuum concentration, oil and gas recovery, etc.

High precision machining equipment

The company cooperates with many scientific research institutions and universities, such as ZheJiang University, China University of petroleum, ZheJiang Institute of mechanical design, etc.with colleges and universities to research and develop core technologies, and owns dozens of independent intellectual property patents.Our technology is leading, the product quality is stable, the product has a good reputation in China’s domestic market, is sold all over the country, and is exported to Europe, America, Africa, the Middle East and Southeast Asia,We adhering to the basic tenet of quality, reputation and service, the company takes leading-edge technology of vacuum pump as its own responsibility, and wholeheartedly serves customers of vacuum equipment application in various industries with rigorous working attitude and professional working style.

Product quality wins consumer cooperationIn shipmentISO 9001

High tech enterprise certificate

Welcome to send your needs, we will provide you with the best service,

provide the greatest help!!!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | One Year |

|---|---|

| Oil or Not: | Oil Free |

| Structure: | Screw |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Work Function: | Mainsuction Pump |

| Customization: |

Available

|

|

|---|

How Are Roots Vacuum Pumps Utilized in the Automotive Industry?

Roots vacuum pumps play a significant role in various applications within the automotive industry. Here’s a detailed explanation:

1. Brake System Vacuum Pumps:

– Vacuum Boosters: Roots vacuum pumps are commonly used as vacuum boosters in automotive brake systems. They assist in enhancing the braking performance by providing the necessary vacuum for power brake operation. When the driver applies the brake pedal, the vacuum booster uses the suction power generated by the Roots pump to amplify the force applied to the brake master cylinder, resulting in more effective braking.

– Electric Brake Vacuum Pumps: In modern electric or hybrid vehicles, where traditional engine-driven vacuum sources may not be available, electric brake vacuum pumps are utilized. These pumps, often based on the Roots principle, generate vacuum independently to power the brake booster and ensure reliable braking performance.

2. Emissions Control:

– Evaporative Emission Control: Roots vacuum pumps are employed in evaporative emission control systems to prevent the release of harmful vapors from the fuel system into the atmosphere. These pumps create a vacuum within the system, purging and storing fuel vapors in a canister for subsequent combustion or recycling.

– Positive Crankcase Ventilation (PCV): PCV systems, which are designed to reduce emissions and maintain the integrity of the engine, also utilize Roots vacuum pumps. These pumps draw crankcase gases and vapors, including oil mist, from the engine’s crankcase into the intake manifold for combustion, improving overall engine efficiency and reducing pollution.

3. Engine Testing and Development:

– Vacuum Leakage Testing: Roots vacuum pumps are utilized for vacuum leakage testing in engine manufacturing and development. By creating a vacuum in the intake manifold or other engine components, these pumps enable the detection of leaks and ensure the integrity of the engine’s air delivery system.

– Air Flow Calibration: During engine testing and calibration, Roots vacuum pumps are used to simulate various operating conditions by controlling the intake air flow. This allows engineers to fine-tune the engine’s performance, optimize fuel-air mixture ratios, and assess the engine’s efficiency and emissions characteristics.

4. HVAC Systems:

– Climate Control: Roots vacuum pumps are employed in automotive HVAC (Heating, Ventilation, and Air Conditioning) systems to facilitate the flow and distribution of air. These pumps help regulate the operation of HVAC components, such as air blend doors and vacuum actuators, ensuring proper air temperature and direction control inside the vehicle cabin.

5. Fuel System and Turbocharging:

– Fuel Transfer and Evacuation: In automotive fuel systems, Roots vacuum pumps are used for fuel transfer and evacuation. These pumps assist in priming the fuel system, removing air pockets, and ensuring the continuous flow of fuel to the engine, enhancing the overall fuel delivery performance.

– Turbocharger Control: Roots vacuum pumps are sometimes employed in turbocharged engines to control the actuation of variable geometry turbochargers (VGT). These pumps provide the necessary vacuum signals to actuate the VGT mechanism, optimizing turbocharger performance and enhancing engine efficiency.

6. Other Applications:

– Electric Vehicle Battery Systems: In electric vehicles, Roots vacuum pumps are utilized to create a vacuum in battery enclosures, helping to maintain the integrity and safety of the battery system by preventing the ingress of moisture, dust, or contaminants.

– Engine Air Induction: Some automotive engines utilize Roots-type superchargers or twin-screw superchargers, which are essentially positive displacement Roots vacuum pumps operating in reverse. These devices compress and force air into the engine’s intake manifold, resulting in increased engine power and performance.

In summary, Roots vacuum pumps find extensive utilization in the automotive industry. They play a crucial role in brake systems, emissions control, engine testing and development, HVAC systems, fuel systems, turbocharging, electric vehicle battery systems, and engine air induction. By contributing to braking performance, emissions reduction, engine calibration, HVAC functionality, fuel system efficiency, turbocharger control, battery system safety, and engine power enhancement, Roots vacuum pumps contribute significantly to the overall operation and performance of automotive systems and components.

What Is a Roots Vacuum Pump, and How Does It Work?

A Roots vacuum pump, also known as a Roots blower or a rotary lobe pump, is a type of positive displacement vacuum pump that is widely used for various industrial applications. Here’s a detailed explanation of what a Roots vacuum pump is and how it works:

A Roots vacuum pump consists of two synchronized rotors, known as lobes or impellers, that rotate in opposite directions within a housing. The lobes have a unique helical shape with multiple lobes, which allows them to trap and move gas efficiently. The rotors are synchronized with the help of timing gears to maintain precise clearances between the lobes and the housing.

The operation of a Roots vacuum pump can be described in the following steps:

1. Inlet Stage: The process begins with the lobes rotating in opposite directions. As the lobes rotate, the volume between them and the housing gradually increases, creating a larger space at the inlet side of the pump. This expansion of the volume causes the gas to enter the pump through the inlet port. The gas is drawn in due to the pressure difference between the inlet and the pump’s internal chamber.

2. Compression Stage: As the gas enters the pump, it gets trapped in the spaces between the lobes and the housing. As the lobes continue to rotate, the trapped gas gets carried along the rotating lobes. The gas is essentially trapped in the pockets formed by the lobes and the housing. The rotating lobes then compress the gas as they move towards the outlet side of the pump.

3. Outlet Stage: As the lobes approach the outlet side of the pump, the volume between them and the housing decreases, resulting in the compression of the trapped gas. This compression raises the pressure of the gas, causing it to be expelled through the outlet port of the pump. The expelled gas is then discharged into the atmosphere or directed to a downstream process or another vacuum pump, depending on the application.

It’s important to note that a Roots vacuum pump operates as a non-contacting pump, meaning that there is no physical contact between the lobes or between the lobes and the housing. This characteristic eliminates the need for lubrication within the pump and reduces the risk of contamination or oil vapor backstreaming into the vacuum system.

Roots vacuum pumps are known for their high pumping speed and ability to handle large volumes of gas. However, they are not capable of achieving high vacuum levels on their own. To achieve higher vacuum levels, a Roots pump is often used in conjunction with other vacuum pumps, such as rotary vane pumps or diffusion pumps, in a hybrid or combination pumping system.

In summary, a Roots vacuum pump operates based on the principle of positive displacement. It utilizes synchronized rotating lobes to trap and compress gas, allowing it to be discharged at a higher pressure. The non-contacting design of the pump eliminates the need for lubrication and reduces the risk of contamination. Roots vacuum pumps are commonly employed in various industrial applications, especially when high pumping speed and large gas handling capacity are required.

editor by Dream 2024-05-15