Product Description

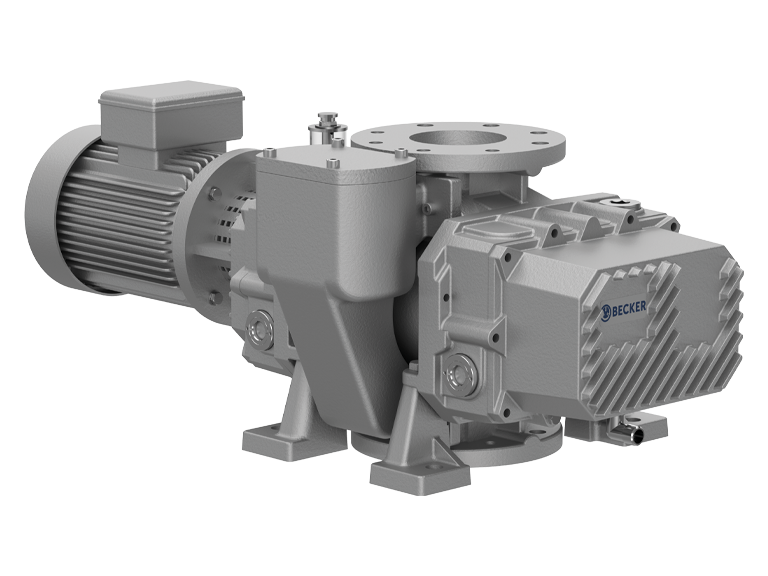

Paper Product Machinery Roots Vacuum Pump for 2571 New Business Manufacture

Product Description

Roots vacuum pump is also known as the mechnical booster which is a positive displacement type pump. It is 1 of the special pumps which can reach middle, high vacuum rang. Its work principle is similar to the Root fan. Both of them used a pair of rotors, whose shape looks like 8, to achieve the suction and discharge process.According to the technical that the plenty of vapor and solvent is required to pump in the mechnical, pharmacy areas, we have improved the seal type of the bearing housing and gear box of the ZJ series Roots pump to reduce the emulsification of the pump oil efficiently and make the Roots pump more suitable to assemble with the water ring vacuum pump to suction more vapor and solvent

Technical Parameters

| 1 | Product name | roots vacuum pump | |||||||||||

| 2 | Model | AT1 | AT2 | AT3 | AT4 | ||||||||

| 3 | Max.extraction quanlity (m3/min) | 6 | 10 | 15 | 30 | ||||||||

| 4 | number of revolutions (r/min) | 400 | 450 | 400 | 400 | ||||||||

| 5 | useful vacuum degree (Pa) | 53.3×103(That’s equivalent to less than 400mmHg) | |||||||||||

| 6 | final vacuum (Pa) | 90.66×103(That’s equivalent to less than 680mmHg) | |||||||||||

| 7 | inlet and outlet diameter (mm) | 125 | 100 | 200 | 250 | ||||||||

| 8 | motor | Y160M-6 705KW | Y160L-4 15KW | Y200L2-6 22KW | Y280S-6 45KW | ||||||||

| 9 | dimensions(LxWxH) (mm) | 894×580×832 | 1014×580×902 | 1040×755×1077 | 1480×875×1300 | ||||||||

Our Company

About us:

CHINAMFG Machinery Manufacturing Co., Ltd.Was founded in 1985, according to the modern enterprise mechanism into a large-scale standardized joint-stock enterprises, with 278 workers,including 23 engineers and technicians,15 senior engineers.In general, CHINAMFG is in the leading place of paper-making industry in China

Our Service&Customers feedback

Advantage:

Part 1:

1)Low MOQ:It can meet your low qty demand very well.

2)Good Service:We treat clients business as our own business.

3)Good Quality:We have strict QC quality control system .Good reputation in the market.

4)Fast & Cheap Delivery:We have big discount from shipping forwarder (Long Contract).

Part 2:

1.We have rich experience in this industy;

2.We are the factory outlet ,can give you a cheaper price ;

3.For the machine,we have complete paper machinery with top quality.

Before Purchase:

1.Help customers find the right product by professional technology and business consultation

2.Provide plans of the machines installation freely

3.Make customized products according to the clients requirements

4.Online for 24 hours

After purchase:

1.Fast and saft delivery

2.Assist our clients to bulid the equipment

3.Train the first-line operators on site

4.Regularly visit clients to solve production problems

5.Online for 24 hours

Packing & Delivery

Packing Details :Spray antirust oil on machine surface and cover PE film, thenpacked in wooden box in the container(including all parts)

Delivery Details :40 days

Certification

All products has been certified.

Customers&Exhibition

This is our customers from all over the world,our company goes to the exhibition every year.

FAQ

1.Q:Can you put my brand name on these products?

A:Yes, we can.

2.Q:What is your usual payment conditions?

A:FOB 30% advanced payment, full payment before delivery, by T/T.

3.Q:Can you provide sample for us?

A:It depends on. If the products you need are standard and we have stock, we will provide.If not, we can

not provide for you immediately. The freight will be payed by buyer.

4.Q:Why choose us?

A:Direct price, gurantee quality, 24H service.

Contact Me

Any questions you can contact me,24 hours service for you!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | on Line |

|---|---|

| Warranty: | One Year |

| Max.Head: | 10-30m |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How Are Roots Vacuum Pumps Utilized in the Automotive Industry?

Roots vacuum pumps play a significant role in various applications within the automotive industry. Here’s a detailed explanation:

1. Brake System Vacuum Pumps:

– Vacuum Boosters: Roots vacuum pumps are commonly used as vacuum boosters in automotive brake systems. They assist in enhancing the braking performance by providing the necessary vacuum for power brake operation. When the driver applies the brake pedal, the vacuum booster uses the suction power generated by the Roots pump to amplify the force applied to the brake master cylinder, resulting in more effective braking.

– Electric Brake Vacuum Pumps: In modern electric or hybrid vehicles, where traditional engine-driven vacuum sources may not be available, electric brake vacuum pumps are utilized. These pumps, often based on the Roots principle, generate vacuum independently to power the brake booster and ensure reliable braking performance.

2. Emissions Control:

– Evaporative Emission Control: Roots vacuum pumps are employed in evaporative emission control systems to prevent the release of harmful vapors from the fuel system into the atmosphere. These pumps create a vacuum within the system, purging and storing fuel vapors in a canister for subsequent combustion or recycling.

– Positive Crankcase Ventilation (PCV): PCV systems, which are designed to reduce emissions and maintain the integrity of the engine, also utilize Roots vacuum pumps. These pumps draw crankcase gases and vapors, including oil mist, from the engine’s crankcase into the intake manifold for combustion, improving overall engine efficiency and reducing pollution.

3. Engine Testing and Development:

– Vacuum Leakage Testing: Roots vacuum pumps are utilized for vacuum leakage testing in engine manufacturing and development. By creating a vacuum in the intake manifold or other engine components, these pumps enable the detection of leaks and ensure the integrity of the engine’s air delivery system.

– Air Flow Calibration: During engine testing and calibration, Roots vacuum pumps are used to simulate various operating conditions by controlling the intake air flow. This allows engineers to fine-tune the engine’s performance, optimize fuel-air mixture ratios, and assess the engine’s efficiency and emissions characteristics.

4. HVAC Systems:

– Climate Control: Roots vacuum pumps are employed in automotive HVAC (Heating, Ventilation, and Air Conditioning) systems to facilitate the flow and distribution of air. These pumps help regulate the operation of HVAC components, such as air blend doors and vacuum actuators, ensuring proper air temperature and direction control inside the vehicle cabin.

5. Fuel System and Turbocharging:

– Fuel Transfer and Evacuation: In automotive fuel systems, Roots vacuum pumps are used for fuel transfer and evacuation. These pumps assist in priming the fuel system, removing air pockets, and ensuring the continuous flow of fuel to the engine, enhancing the overall fuel delivery performance.

– Turbocharger Control: Roots vacuum pumps are sometimes employed in turbocharged engines to control the actuation of variable geometry turbochargers (VGT). These pumps provide the necessary vacuum signals to actuate the VGT mechanism, optimizing turbocharger performance and enhancing engine efficiency.

6. Other Applications:

– Electric Vehicle Battery Systems: In electric vehicles, Roots vacuum pumps are utilized to create a vacuum in battery enclosures, helping to maintain the integrity and safety of the battery system by preventing the ingress of moisture, dust, or contaminants.

– Engine Air Induction: Some automotive engines utilize Roots-type superchargers or twin-screw superchargers, which are essentially positive displacement Roots vacuum pumps operating in reverse. These devices compress and force air into the engine’s intake manifold, resulting in increased engine power and performance.

In summary, Roots vacuum pumps find extensive utilization in the automotive industry. They play a crucial role in brake systems, emissions control, engine testing and development, HVAC systems, fuel systems, turbocharging, electric vehicle battery systems, and engine air induction. By contributing to braking performance, emissions reduction, engine calibration, HVAC functionality, fuel system efficiency, turbocharger control, battery system safety, and engine power enhancement, Roots vacuum pumps contribute significantly to the overall operation and performance of automotive systems and components.

What Is a Roots Vacuum Pump, and How Does It Work?

A Roots vacuum pump, also known as a Roots blower or a rotary lobe pump, is a type of positive displacement vacuum pump that is widely used for various industrial applications. Here’s a detailed explanation of what a Roots vacuum pump is and how it works:

A Roots vacuum pump consists of two synchronized rotors, known as lobes or impellers, that rotate in opposite directions within a housing. The lobes have a unique helical shape with multiple lobes, which allows them to trap and move gas efficiently. The rotors are synchronized with the help of timing gears to maintain precise clearances between the lobes and the housing.

The operation of a Roots vacuum pump can be described in the following steps:

1. Inlet Stage: The process begins with the lobes rotating in opposite directions. As the lobes rotate, the volume between them and the housing gradually increases, creating a larger space at the inlet side of the pump. This expansion of the volume causes the gas to enter the pump through the inlet port. The gas is drawn in due to the pressure difference between the inlet and the pump’s internal chamber.

2. Compression Stage: As the gas enters the pump, it gets trapped in the spaces between the lobes and the housing. As the lobes continue to rotate, the trapped gas gets carried along the rotating lobes. The gas is essentially trapped in the pockets formed by the lobes and the housing. The rotating lobes then compress the gas as they move towards the outlet side of the pump.

3. Outlet Stage: As the lobes approach the outlet side of the pump, the volume between them and the housing decreases, resulting in the compression of the trapped gas. This compression raises the pressure of the gas, causing it to be expelled through the outlet port of the pump. The expelled gas is then discharged into the atmosphere or directed to a downstream process or another vacuum pump, depending on the application.

It’s important to note that a Roots vacuum pump operates as a non-contacting pump, meaning that there is no physical contact between the lobes or between the lobes and the housing. This characteristic eliminates the need for lubrication within the pump and reduces the risk of contamination or oil vapor backstreaming into the vacuum system.

Roots vacuum pumps are known for their high pumping speed and ability to handle large volumes of gas. However, they are not capable of achieving high vacuum levels on their own. To achieve higher vacuum levels, a Roots pump is often used in conjunction with other vacuum pumps, such as rotary vane pumps or diffusion pumps, in a hybrid or combination pumping system.

In summary, a Roots vacuum pump operates based on the principle of positive displacement. It utilizes synchronized rotating lobes to trap and compress gas, allowing it to be discharged at a higher pressure. The non-contacting design of the pump eliminates the need for lubrication and reduces the risk of contamination. Roots vacuum pumps are commonly employed in various industrial applications, especially when high pumping speed and large gas handling capacity are required.

editor by Dream 2024-05-08

China best Culture Paper Mill Pulp Making Machinery Roots Vacuum Pump vacuum pump

Product Description

Culture Paper Mill Pulp Making Machinery Roots Vacuum Pump

Technical Parameters

Roots vacuum pump is characterized by: quick start, less power consumption, low operation and maintenance costs, pumping speed, high efficiency, to be pumped gas contained in a small amount of steam and dust is not sensitive, in the range of 100 ~ 1 pa pressure has a large pumping rate, can quickly exclude the sudden release of air. Widely used in petroleum, chemical, metallurgy, textile, papermaking and other industries.

Technical Parmeters

|

Roots vacuum Pump |

||||||

|

Model |

ZBK33 |

ZBK13 |

ZBK15 |

ZBK16 |

ZBK17 |

ZBK18 |

|

Max.extraction quantity(m³/min) |

3.8 |

6 |

10 |

15 |

30 |

60 |

|

Rated extraction quantity(m³/min) |

3.1 |

4.2 |

7.5 |

11 |

22 |

47 |

|

Rated vacuum degree(kpa) |

33.3 |

33.3 |

40 |

40 |

45 |

47 |

|

Rated Rotation Speed(r/min) |

500 |

400 |

450 |

400 |

400 |

550 |

|

Inlet and outlet diameter(mm) |

Φ85 |

Φ125 |

Φ150 |

Φ200 |

Φ250 |

Φ300 |

|

Equipped Motor |

Y112M- 4-4KW |

Y160M- 6-7.5KW |

Y160L- 4-15KW |

Y200L2- 6-22KW |

Y280S- 6-45KW |

Y315M- 6-90KW |

|

Equipped V-Belt |

A-1550 |

B-2800 |

B-2800 |

B-3550 |

D-4500 |

D-4000 |

|

Weight(kg) |

200 |

440 |

535 |

890 |

2100 |

3500 |

|

Overall size(L×W×H) mm |

682×359× 575 |

906×583× 915 |

967×578× 950 |

1019×748× 1205 |

1340×857× 1550 |

2205×2934 ×2190 |

Hot Sales

These are all our hottest products.

Both the quality and the price are highly appraised by customers.

Company Information

Aotian Machinery Manufacturing Co., Ltd. was founded in 1985, according to the modern enterprise mechanism into a large-scale standardized joint-stock enterprises, with 278 workers,including 23 engineers and technicians,15 senior engineers.In general, CHINAMFG is in the leading place of paper-making industry in China .

We will provide whole services according to our clients’ demand, like technical design, equipment production, installation and test instruction and so on. We will meet and exceed your expectations. Please contact our custom service for details.

Our Customer

These are our clients in Iran ,Pakistan and India.

Our products are sold to more than 100 countries all over the world.

Package & Shipping

Packaging

products will packaged according to their shapes, weight, transport distance and transport modes.Large machines will be packaged in sections.every part export machinery will be in standard export package seaworthy wooden case waterproof film, straw rope, carton box etc

Shipping

sea transportation is from HangZhou seaports or other china main ports.

the delivery time is decided by machine types.But we also try to make it follows your needs.

Customer Feedback

Our Products have sold to many countries,and won customer’s good reputation.

Our Service

Service first

1.To provide you with the transformation and upgrading of plant equipment programs, in order to improve the yield and quality

2.Always online to answer technical questions

3.The customer arrives China, accompanied this translation facility until send customers back

4.send engineers to the customer’s national installation and commissioning of the machine, to ensure the normal operation of the machine

5.Our products can guarantee excellent quality, if there is any quality problems, we flew to your country for your free service

FAQ

1.Q:Are you a manufacture?

A: Yes,we have been in providing the professional products in this field for 30 years.

2.Q:How to install the machine?

A:we can help with the installation by vedio,email,picture.if it is a large project,we can arrange our worker help you to install it in your country.

3.Q:How do you pack the products?

A:Normally as the export standard packaging or as your requirement.

4.Q:What’s your available port of shipment?

A:HangZhou port,ZheJiang port and so on.

5.Q:Is it customized available?

A:Yes,according to your detailed drawing you provided.

Contact Us

As most paper machinery products, pulping equipments, roll products need to be customized, the prices and sample prices shown on our product details page are for reference only, please contact our professional customer service and tell us your specifications and sizes, you will get a more reasonable and exciting price!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 6 Month |

|---|---|

| Warranty: | 6 Month |

| Certification: | RoHS, ISO 9001:2000 |

| Samples: |

US$ 5000/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can Roots Vacuum Pumps Be Used for Vacuum Impregnation in Manufacturing?

Yes, Roots vacuum pumps can be used for vacuum impregnation in manufacturing. Here’s a detailed explanation:

1. Vacuum Impregnation in Manufacturing: Vacuum impregnation is a process used in manufacturing to fill porous materials or components with a liquid or resin. It is commonly employed to enhance the properties of materials by improving their strength, sealing capability, or resistance to chemicals or corrosion. The process involves placing the porous material in a vacuum chamber and removing the air or gas trapped within its pores. Once a vacuum is established, a liquid or resin is introduced, and the vacuum is released, allowing the material to absorb the impregnating substance.

2. Role of Roots Vacuum Pumps: Roots vacuum pumps play a crucial role in the vacuum impregnation process by creating and maintaining the required vacuum conditions. Here’s how they contribute:

– Evacuation: Roots pumps are used to evacuate the impregnation chamber, removing the air and gas from within the pores of the porous material. By creating a vacuum, the trapped gases are extracted, creating a void space for the impregnating substance to penetrate.

– Pressure Control: Roots pumps help control the pressure within the impregnation chamber during different stages of the process. They can rapidly achieve and maintain the desired vacuum level, ensuring proper impregnation of the material and preventing the formation of air bubbles or voids.

– Gas Removal: Roots pumps effectively remove gases released from the impregnating substance during the impregnation process. As the liquid or resin fills the pores of the porous material, gases may be released due to the reaction or outgassing. The vacuum pump evacuates these gases, preventing their accumulation and ensuring complete impregnation.

3. Advantages of Roots Vacuum Pumps for Vacuum Impregnation:

– High Pumping Speed: Roots vacuum pumps have a high pumping speed, enabling rapid evacuation of the impregnation chamber. This reduces the overall impregnation cycle time, increasing manufacturing throughput and efficiency.

– Large Volume Handling: Roots pumps are capable of handling large volumes of gas, allowing them to evacuate chambers of different sizes effectively. This is advantageous when impregnating large or complex-shaped components that require a significant amount of impregnating substance.

– Continuous Operation: Roots pumps can operate continuously, maintaining the vacuum conditions required for impregnation throughout the process. This ensures consistent impregnation results and reduces the risk of incomplete impregnation or material defects.

– Compatibility with Impregnating Substances: Roots vacuum pumps are compatible with a wide range of impregnating substances, including resins, oils, solvents, and other liquids. They can handle different chemical compositions and provide a clean and efficient environment for the impregnation process.

4. Considerations for Vacuum Impregnation:

– Material Compatibility: It is essential to consider the compatibility of the porous material with the impregnating substance and the impregnation process itself. Some materials may require pre-treatment or surface preparation before impregnation. The choice of impregnating substance should also align with the material’s properties and intended application.

– Process Parameters: Vacuum impregnation involves controlling various process parameters, such as vacuum level, impregnation time, pressure release, and curing conditions. These parameters may vary depending on the material, impregnating substance, and desired impregnation results. Proper process optimization and control are crucial for achieving consistent and reliable impregnation outcomes.

– System Design: The design of the vacuum impregnation system should consider factors such as chamber size, gas flow rates, vacuum pump capacity, and pressure control mechanisms. Proper system design ensures efficient operation, reliable vacuum conditions, and effective impregnation of the porous material.

In summary, Roots vacuum pumps are well-suited for vacuum impregnation in manufacturing. Their high pumping speed, large volume handling capability, continuous operation, and compatibility with impregnating substances make them effective in creating and maintaining the required vacuum conditions for successful impregnation. By considering material compatibility, process parameters, and system design, Roots vacuum pumps contribute to the efficient and reliable impregnation of porous materials in various manufacturing applications.

What Is a Roots Vacuum Pump, and How Does It Work?

A Roots vacuum pump, also known as a Roots blower or a rotary lobe pump, is a type of positive displacement vacuum pump that is widely used for various industrial applications. Here’s a detailed explanation of what a Roots vacuum pump is and how it works:

A Roots vacuum pump consists of two synchronized rotors, known as lobes or impellers, that rotate in opposite directions within a housing. The lobes have a unique helical shape with multiple lobes, which allows them to trap and move gas efficiently. The rotors are synchronized with the help of timing gears to maintain precise clearances between the lobes and the housing.

The operation of a Roots vacuum pump can be described in the following steps:

1. Inlet Stage: The process begins with the lobes rotating in opposite directions. As the lobes rotate, the volume between them and the housing gradually increases, creating a larger space at the inlet side of the pump. This expansion of the volume causes the gas to enter the pump through the inlet port. The gas is drawn in due to the pressure difference between the inlet and the pump’s internal chamber.

2. Compression Stage: As the gas enters the pump, it gets trapped in the spaces between the lobes and the housing. As the lobes continue to rotate, the trapped gas gets carried along the rotating lobes. The gas is essentially trapped in the pockets formed by the lobes and the housing. The rotating lobes then compress the gas as they move towards the outlet side of the pump.

3. Outlet Stage: As the lobes approach the outlet side of the pump, the volume between them and the housing decreases, resulting in the compression of the trapped gas. This compression raises the pressure of the gas, causing it to be expelled through the outlet port of the pump. The expelled gas is then discharged into the atmosphere or directed to a downstream process or another vacuum pump, depending on the application.

It’s important to note that a Roots vacuum pump operates as a non-contacting pump, meaning that there is no physical contact between the lobes or between the lobes and the housing. This characteristic eliminates the need for lubrication within the pump and reduces the risk of contamination or oil vapor backstreaming into the vacuum system.

Roots vacuum pumps are known for their high pumping speed and ability to handle large volumes of gas. However, they are not capable of achieving high vacuum levels on their own. To achieve higher vacuum levels, a Roots pump is often used in conjunction with other vacuum pumps, such as rotary vane pumps or diffusion pumps, in a hybrid or combination pumping system.

In summary, a Roots vacuum pump operates based on the principle of positive displacement. It utilizes synchronized rotating lobes to trap and compress gas, allowing it to be discharged at a higher pressure. The non-contacting design of the pump eliminates the need for lubrication and reduces the risk of contamination. Roots vacuum pumps are commonly employed in various industrial applications, especially when high pumping speed and large gas handling capacity are required.

editor by Dream 2024-04-24

China best Paper Product Machinery Roots Vacuum Pump for 2024 New Business Manufacture vacuum pump booster

Product Description

Paper Product Machinery Roots Vacuum Pump for 2571 New Business Manufacture

Product Description

Roots vacuum pump is also known as the mechnical booster which is a positive displacement type pump. It is 1 of the special pumps which can reach middle, high vacuum rang. Its work principle is similar to the Root fan. Both of them used a pair of rotors, whose shape looks like 8, to achieve the suction and discharge process.According to the technical that the plenty of vapor and solvent is required to pump in the mechnical, pharmacy areas, we have improved the seal type of the bearing housing and gear box of the ZJ series Roots pump to reduce the emulsification of the pump oil efficiently and make the Roots pump more suitable to assemble with the water ring vacuum pump to suction more vapor and solvent

Technical Parameters

| 1 | Product name | roots vacuum pump | |||||||||||

| 2 | Model | AT1 | AT2 | AT3 | AT4 | ||||||||

| 3 | Max.extraction quanlity (m3/min) | 6 | 10 | 15 | 30 | ||||||||

| 4 | number of revolutions (r/min) | 400 | 450 | 400 | 400 | ||||||||

| 5 | useful vacuum degree (Pa) | 53.3×103(That’s equivalent to less than 400mmHg) | |||||||||||

| 6 | final vacuum (Pa) | 90.66×103(That’s equivalent to less than 680mmHg) | |||||||||||

| 7 | inlet and outlet diameter (mm) | 125 | 100 | 200 | 250 | ||||||||

| 8 | motor | Y160M-6 705KW | Y160L-4 15KW | Y200L2-6 22KW | Y280S-6 45KW | ||||||||

| 9 | dimensions(LxWxH) (mm) | 894×580×832 | 1014×580×902 | 1040×755×1077 | 1480×875×1300 | ||||||||

Our Company

About us:

CHINAMFG Machinery Manufacturing Co., Ltd.Was founded in 1985, according to the modern enterprise mechanism into a large-scale standardized joint-stock enterprises, with 278 workers,including 23 engineers and technicians,15 senior engineers.In general, CHINAMFG is in the leading place of paper-making industry in China

Our Service&Customers feedback

Advantage:

Part 1:

1)Low MOQ:It can meet your low qty demand very well.

2)Good Service:We treat clients business as our own business.

3)Good Quality:We have strict QC quality control system .Good reputation in the market.

4)Fast & Cheap Delivery:We have big discount from shipping forwarder (Long Contract).

Part 2:

1.We have rich experience in this industy;

2.We are the factory outlet ,can give you a cheaper price ;

3.For the machine,we have complete paper machinery with top quality.

Before Purchase:

1.Help customers find the right product by professional technology and business consultation

2.Provide plans of the machines installation freely

3.Make customized products according to the clients requirements

4.Online for 24 hours

After purchase:

1.Fast and saft delivery

2.Assist our clients to bulid the equipment

3.Train the first-line operators on site

4.Regularly visit clients to solve production problems

5.Online for 24 hours

Packing & Delivery

Packing Details :Spray antirust oil on machine surface and cover PE film, thenpacked in wooden box in the container(including all parts)

Delivery Details :40 days

Certification

All products has been certified.

Customers&Exhibition

This is our customers from all over the world,our company goes to the exhibition every year.

FAQ

1.Q:Can you put my brand name on these products?

A:Yes, we can.

2.Q:What is your usual payment conditions?

A:FOB 30% advanced payment, full payment before delivery, by T/T.

3.Q:Can you provide sample for us?

A:It depends on. If the products you need are standard and we have stock, we will provide.If not, we can

not provide for you immediately. The freight will be payed by buyer.

4.Q:Why choose us?

A:Direct price, gurantee quality, 24H service.

Contact Me

Any questions you can contact me,24 hours service for you!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | on Line |

|---|---|

| Warranty: | One Year |

| Max.Head: | 10-30m |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How Are Roots Vacuum Pumps Utilized in the Automotive Industry?

Roots vacuum pumps play a significant role in various applications within the automotive industry. Here’s a detailed explanation:

1. Brake System Vacuum Pumps:

– Vacuum Boosters: Roots vacuum pumps are commonly used as vacuum boosters in automotive brake systems. They assist in enhancing the braking performance by providing the necessary vacuum for power brake operation. When the driver applies the brake pedal, the vacuum booster uses the suction power generated by the Roots pump to amplify the force applied to the brake master cylinder, resulting in more effective braking.

– Electric Brake Vacuum Pumps: In modern electric or hybrid vehicles, where traditional engine-driven vacuum sources may not be available, electric brake vacuum pumps are utilized. These pumps, often based on the Roots principle, generate vacuum independently to power the brake booster and ensure reliable braking performance.

2. Emissions Control:

– Evaporative Emission Control: Roots vacuum pumps are employed in evaporative emission control systems to prevent the release of harmful vapors from the fuel system into the atmosphere. These pumps create a vacuum within the system, purging and storing fuel vapors in a canister for subsequent combustion or recycling.

– Positive Crankcase Ventilation (PCV): PCV systems, which are designed to reduce emissions and maintain the integrity of the engine, also utilize Roots vacuum pumps. These pumps draw crankcase gases and vapors, including oil mist, from the engine’s crankcase into the intake manifold for combustion, improving overall engine efficiency and reducing pollution.

3. Engine Testing and Development:

– Vacuum Leakage Testing: Roots vacuum pumps are utilized for vacuum leakage testing in engine manufacturing and development. By creating a vacuum in the intake manifold or other engine components, these pumps enable the detection of leaks and ensure the integrity of the engine’s air delivery system.

– Air Flow Calibration: During engine testing and calibration, Roots vacuum pumps are used to simulate various operating conditions by controlling the intake air flow. This allows engineers to fine-tune the engine’s performance, optimize fuel-air mixture ratios, and assess the engine’s efficiency and emissions characteristics.

4. HVAC Systems:

– Climate Control: Roots vacuum pumps are employed in automotive HVAC (Heating, Ventilation, and Air Conditioning) systems to facilitate the flow and distribution of air. These pumps help regulate the operation of HVAC components, such as air blend doors and vacuum actuators, ensuring proper air temperature and direction control inside the vehicle cabin.

5. Fuel System and Turbocharging:

– Fuel Transfer and Evacuation: In automotive fuel systems, Roots vacuum pumps are used for fuel transfer and evacuation. These pumps assist in priming the fuel system, removing air pockets, and ensuring the continuous flow of fuel to the engine, enhancing the overall fuel delivery performance.

– Turbocharger Control: Roots vacuum pumps are sometimes employed in turbocharged engines to control the actuation of variable geometry turbochargers (VGT). These pumps provide the necessary vacuum signals to actuate the VGT mechanism, optimizing turbocharger performance and enhancing engine efficiency.

6. Other Applications:

– Electric Vehicle Battery Systems: In electric vehicles, Roots vacuum pumps are utilized to create a vacuum in battery enclosures, helping to maintain the integrity and safety of the battery system by preventing the ingress of moisture, dust, or contaminants.

– Engine Air Induction: Some automotive engines utilize Roots-type superchargers or twin-screw superchargers, which are essentially positive displacement Roots vacuum pumps operating in reverse. These devices compress and force air into the engine’s intake manifold, resulting in increased engine power and performance.

In summary, Roots vacuum pumps find extensive utilization in the automotive industry. They play a crucial role in brake systems, emissions control, engine testing and development, HVAC systems, fuel systems, turbocharging, electric vehicle battery systems, and engine air induction. By contributing to braking performance, emissions reduction, engine calibration, HVAC functionality, fuel system efficiency, turbocharger control, battery system safety, and engine power enhancement, Roots vacuum pumps contribute significantly to the overall operation and performance of automotive systems and components.

What Are the Primary Applications of Roots Vacuum Pumps?

Roots vacuum pumps, also known as Roots blowers or rotary lobe pumps, are utilized in a variety of industrial applications where efficient and reliable vacuum generation is required. Here’s a detailed explanation of the primary applications of Roots vacuum pumps:

1. Chemical Processing: Roots vacuum pumps find extensive use in the chemical processing industry. They are employed for processes such as vacuum distillation, solvent recovery, drying, and degassing. Their high pumping speed and ability to handle corrosive gases make them suitable for handling various chemical vapors and byproducts.

2. Pharmaceuticals: In the pharmaceutical industry, Roots vacuum pumps are utilized for applications such as vacuum drying, tablet coating, freeze drying, and vacuum packaging. Their oil-free operation ensures a clean and contaminant-free vacuum environment, which is crucial for pharmaceutical manufacturing processes.

3. Food Processing: Roots vacuum pumps play a significant role in the food processing industry. They are employed for vacuum packaging, vacuum cooling, and vacuum drying of food products. The oil-free operation of Roots vacuum pumps ensures food safety and eliminates the risk of contamination.

4. Environmental Technology: Roots vacuum pumps are utilized in environmental technology applications, including wastewater treatment, biogas processing, and air pollution control. They are employed to extract gases, control emissions, and facilitate the treatment and purification of air and water.

5. Semiconductor Manufacturing: In the semiconductor industry, Roots vacuum pumps are used for processes such as ion implantation, physical vapor deposition (PVD), chemical vapor deposition (CVD), and etching. Their high pumping speed and oil-free operation are crucial for maintaining clean vacuum conditions required in semiconductor fabrication.

6. Packaging and Printing: Roots vacuum pumps are employed in packaging and printing applications. They are used for vacuum packaging of products, vacuum forming of packaging materials, and in printing presses for paper handling and ink transfer.

7. Automotive Industry: Roots vacuum pumps find application in the automotive industry for processes such as brake system vacuum assist, crankcase ventilation, and emissions control systems. They help create vacuum conditions required for the operation of various automotive systems.

8. Research and Laboratory: Roots vacuum pumps are utilized in research laboratories and scientific facilities for a wide range of applications. They are used in vacuum ovens, freeze dryers, vacuum filtration, electron microscopy, surface analysis, and other laboratory processes that require controlled vacuum environments.

9. Energy Industry: In the energy sector, Roots vacuum pumps are used for applications such as steam turbine condenser air extraction, transformer drying, and vacuum impregnation of electrical components. They help maintain proper vacuum conditions for efficient and reliable operation of energy systems.

These are some of the primary applications where Roots vacuum pumps are commonly used. Their high pumping speed, large gas handling capacity, oil-free operation, reliability, and versatility make them suitable for a wide range of industrial processes that require efficient and reliable vacuum generation.

editor by Dream 2024-04-19

China Custom Paper Making Machinery Outlet Pulping Equipment Roots Vacuum Pump vacuum pump diy

Product Description

Paper making machinery outlet pulping equipment roots vacuum pump

Product description

Roots vacuum pump is also known as the mechnical booster which is a positive displacement type pump. It is 1 of the special pumps which can reach middle, high vacuum rang. Its work principle is similar to the Root fan. Both of them used a pair of rotors, whose shape looks like 8, to achieve the suction and discharge process.According to the technical that the plenty of vapor and solvent is required to pump in the mechnical, pharmacy areas, we have improved the seal type of the bearing housing and gear box of the ZJ series Roots pump to reduce the emulsification of the pump oil efficiently and make the Roots pump more suitable to assemble with the water ring vacuum pump to suction more vapor and solvent .

| Product name | Roots vacuum pump |

| Model | ZBK16 |

| Max pumping | 15m³/min |

| Rated pumping | 11m³/min |

| Rated vacuum | 40kpa |

| Rated rotary speed | 400r/min |

| Input output diameter | 200mm |

| Motor power | 22kw |

| Equip V-belt | B-type 4500 |

| Weight | 890kg |

| SIZE | 1100*750*1250mm |

| Material | Cast iron(HT250) |

Hot sales

There are our best selling products,the quality is praised by customers all over the world.

Company information

Aotian Machinery Manufacturing Co., Ltd.

Trade market:

Our machines sell good in more than 30 countries,such as Nigeria, Egypt, Uzibekistan, Pakistan, America,Uganda,Turkey,Brazil,Fiji,Paraguay,Syria,Lybia,Ethiopia,etc.We have established good relationship with many foreign countries because of our good quality and perfect service.Also we have good relationship with local traders.

What we can provide:

1.1092,1575,1760,1880,2400,2640,2800,3200mm paper machine

2.pulp making equipment

3.paper making equipment

4.paper processing equipment

Best Service:

1.We will provide you all technical consultation and make the drawing and proposal for you.

2.We will send technicians to install and test the machine fo you.

3.We will train skilled workers for you.

4.We will supply best pre-sale, after-sales for you.

Certificate

The company has passed ISO9001:2000 international quality management system certification, self-supporting and export rights.

Exhibition

We go to world famous exhibitions every year.

Constantly promote and publicize the company’s brand, to the majority of customers to show the strength and image of the company.The high concentration of visitor flow, information flow and capital flow in the exhibition can help our company learn from each other and improve its competitiveness.

Company team building

Our company holds a team building every month to enhance team cohesion and promote the feelings between employees, so we are a happy family

Our Service

Before Purchase

1.Offering comprehensive technical and business consultation services;

2.Proposing the most suitable scheme and equipment for our clients;

3.Designing and fabricating targeted products according to the special requirements of clients;

4.Training periodically high qualified service technician.

After purchase

1.Highly inspecting equipment in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3.Assisting our clients for foundation construction of equipment;

4.Dispatching engineers to install and debug equipment;

5.Training the first-line operators on site;

6.Regularly visit clients to solve production problems;

7.Providing life-long maintenance service;

8.Providing technical exchanging;

Our customer

Our machines sell good in more than 30 countries,such as Nigeria, Egypt, Uzibekistan, Pakistan, America,Uganda,Turkey,Brazil,Fiji,Paraguay,Syria,Lybia,Ethiopia,etc.

We have established good relationship with many foreign countries because of our good quality and perfect service.

Packaging&shipping

Packaging

Products will packaged according to their shapes, weight, transport distance and transport modes.

Large machines will be packaged in sections.every part export machinery will be in standard export package seaworthy wooden case waterproof film, straw rope, carton box etc.

Shipping

Sea transportation is from HangZhou seaports or other china main ports.

The delivery time is decided by machine types.But we also try to make it follows your needs.

FAQ

1.Q:Are you a manufacture?

A: Yes,we have been in providing the professional products in this field for 30 years.

2.Q:How to install the machine?

A:we can help with the installation by video,email,picture.if it is a large project,we can arrange our worker help you to install it in your country.

3.Q:How do you pack the products?

A:Normally as the export standard packaging or as your requirement.

4.Q:What’s your available port of shipment?

A:HangZhou port,ZheJiang port and so on.

5.Q:Is it customized available?

A:Yes,according to your detailed drawing you provided.

Any questions, please do not hesitate to contact me.

Thank you!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Certification: | ISO 9001:2000, CE |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What Is the Significance of Roots Vacuum Pumps in the Aerospace Sector?

Roots vacuum pumps play a significant role in various applications within the aerospace sector. Here’s a detailed explanation:

1. Space Simulation Chambers:

– Vacuum Simulation: Roots vacuum pumps are utilized in space simulation chambers to create and maintain vacuum conditions similar to the space environment. These chambers are used to test and simulate the performance of aerospace components and systems under low-pressure conditions, including the effects of vacuum on materials, electronics, and mechanical systems.

– Thermal Vacuum Testing: Roots pumps are crucial in thermal vacuum testing, where aerospace components and systems are subjected to extreme temperature and vacuum conditions. The pumps help evacuate the test chamber and maintain the required vacuum level, enabling accurate thermal testing and evaluation of aerospace equipment’s performance and functionality in space-like conditions.

2. Propellant Handling and Storage:

– Rocket Engine Testing: Roots vacuum pumps are employed in rocket engine testing facilities for propellant handling and storage. They assist in creating a vacuum environment during the propellant loading and purging processes, ensuring the removal of air or contaminants from the propellant tanks and lines. This helps maintain the propellant’s quality and prevents potential issues, such as cavitation or gas bubble formation, that could affect engine performance.

– Fuel Systems: Roots pumps are used in aerospace fuel systems to evacuate and degas the fuel tanks, ensuring the removal of air or gas bubbles that may compromise fuel delivery and engine operation. These pumps contribute to the overall efficiency, reliability, and safety of fuel systems in aerospace vehicles.

3. Environmental Control Systems (ECS):

– Cabin Pressure Control: Roots vacuum pumps are utilized in the environmental control systems of aircraft and spacecraft to help control cabin pressure. By creating a vacuum or adjusting the air circulation, these pumps assist in maintaining the desired cabin pressure levels, ensuring passenger comfort, and providing a safe and controlled environment during flight.

4. Avionics and Electronics:

– Electronic Component Testing: Roots vacuum pumps are employed in the testing and validation of avionics and electronic components used in aerospace applications. These pumps assist in creating a controlled vacuum environment during testing, allowing engineers to evaluate the performance, reliability, and durability of electronic systems under low-pressure conditions.

– Vacuum Encapsulation: In certain aerospace applications, electronic components or circuits may require vacuum encapsulation for protection against harsh environmental conditions, including high altitude, temperature variations, or moisture. Roots vacuum pumps are utilized to create the necessary vacuum environment for the encapsulation process, ensuring the integrity and longevity of sensitive electronics.

5. Space Propulsion Systems:

– Ion Thrusters and Electric Propulsion: Roots vacuum pumps are integral components of ion thrusters and electric propulsion systems used in spacecraft. These pumps aid in the creation and maintenance of the high vacuum conditions required for the operation of these advanced propulsion technologies. They contribute to the efficient exhaust gas removal, ensuring optimal thrust generation and fuel efficiency.

6. Satellite Manufacturing and Testing:

– Satellite Chamber Evacuation: Roots vacuum pumps are utilized in satellite manufacturing and testing facilities for the evacuation of satellite chambers. These pumps help create the required vacuum conditions during satellite assembly, testing, and payload integration, ensuring the cleanliness, functionality, and performance of satellite systems and instruments.

In summary, Roots vacuum pumps have significant significance in the aerospace sector. They are utilized in space simulation chambers, propellant handling and storage, environmental control systems, avionics and electronics testing, space propulsion systems, and satellite manufacturing and testing. By creating and maintaining vacuum conditions, Roots pumps contribute to the performance, reliability, and safety of aerospace components, systems, and vehicles. They play a vital role in supporting space exploration, satellite communication, and the advancement of aerospace technologies.

Are Roots Vacuum Pumps Used in Industrial Applications?

Yes, Roots vacuum pumps are widely used in various industrial applications. Here’s a detailed explanation of their application in industrial settings:

1. Chemical Processing: Roots vacuum pumps find extensive use in the chemical processing industry. They are employed for processes such as vacuum distillation, solvent recovery, drying, and degassing. Their high pumping speed and ability to handle corrosive gases make them suitable for handling various chemical vapors and byproducts.

2. Pharmaceuticals: In the pharmaceutical industry, Roots vacuum pumps are utilized for applications such as vacuum drying, tablet coating, freeze drying, and vacuum packaging. Their oil-free operation ensures a clean and contaminant-free vacuum environment, which is crucial for pharmaceutical manufacturing processes.

3. Food Processing: Roots vacuum pumps play a significant role in the food processing industry. They are employed for vacuum packaging, vacuum cooling, and vacuum drying of food products. The oil-free operation of Roots vacuum pumps ensures food safety and eliminates the risk of contamination.

4. Environmental Technology: Roots vacuum pumps are utilized in environmental technology applications, including wastewater treatment, biogas processing, and air pollution control. They are employed to extract gases, control emissions, and facilitate the treatment and purification of air and water.

5. Semiconductor Manufacturing: In the semiconductor industry, Roots vacuum pumps are used for processes such as ion implantation, physical vapor deposition (PVD), chemical vapor deposition (CVD), and etching. Their high pumping speed and oil-free operation are crucial for maintaining clean vacuum conditions required in semiconductor fabrication.

6. Packaging and Printing: Roots vacuum pumps are employed in packaging and printing applications. They are used for vacuum packaging of products, vacuum forming of packaging materials, and in printing presses for paper handling and ink transfer.

7. Automotive Industry: Roots vacuum pumps find application in the automotive industry for processes such as brake system vacuum assist, crankcase ventilation, and emissions control systems. They help create vacuum conditions required for the operation of various automotive systems.

8. Research and Laboratory: Roots vacuum pumps are utilized in research laboratories and scientific facilities for a wide range of applications. They are used in vacuum ovens, freeze dryers, vacuum filtration, electron microscopy, surface analysis, and other laboratory processes that require controlled vacuum environments.

9. Energy Industry: In the energy sector, Roots vacuum pumps are used for applications such as steam turbine condenser air extraction, transformer drying, and vacuum impregnation of electrical components. They help maintain proper vacuum conditions for efficient and reliable operation of energy systems.

These are just a few examples of the industrial applications where Roots vacuum pumps are commonly used. Their high pumping speed, large gas handling capacity, oil-free operation, reliability, and versatility make them suitable for a wide range of industrial processes that require efficient and reliable vacuum generation.

editor by CX 2024-04-03

China Good quality Culture Paper Mill Pulp Making Machinery Roots Vacuum Pump a/c vacuum pump

Product Description

Culture Paper Mill Pulp Making Machinery Roots Vacuum Pump

Technical Parameters

Roots vacuum pump is characterized by: quick start, less power consumption, low operation and maintenance costs, pumping speed, high efficiency, to be pumped gas contained in a small amount of steam and dust is not sensitive, in the range of 100 ~ 1 pa pressure has a large pumping rate, can quickly exclude the sudden release of air. Widely used in petroleum, chemical, metallurgy, textile, papermaking and other industries.

Technical Parmeters

|

Roots vacuum Pump |

||||||

|

Model |

ZBK33 |

ZBK13 |

ZBK15 |

ZBK16 |

ZBK17 |

ZBK18 |

|

Max.extraction quantity(m³/min) |

3.8 |

6 |

10 |

15 |

30 |

60 |

|

Rated extraction quantity(m³/min) |

3.1 |

4.2 |

7.5 |

11 |

22 |

47 |

|

Rated vacuum degree(kpa) |

33.3 |

33.3 |

40 |

40 |

45 |

47 |

|

Rated Rotation Speed(r/min) |

500 |

400 |

450 |

400 |

400 |

550 |

|

Inlet and outlet diameter(mm) |

Φ85 |

Φ125 |

Φ150 |

Φ200 |

Φ250 |

Φ300 |

|

Equipped Motor |

Y112M- 4-4KW |

Y160M- 6-7.5KW |

Y160L- 4-15KW |

Y200L2- 6-22KW |

Y280S- 6-45KW |

Y315M- 6-90KW |

|

Equipped V-Belt |

A-1550 |

B-2800 |

B-2800 |

B-3550 |

D-4500 |

D-4000 |

|

Weight(kg) |

200 |

440 |

535 |

890 |

2100 |

3500 |

|

Overall size(L×W×H) mm |

682×359× 575 |

906×583× 915 |

967×578× 950 |

1019×748× 1205 |

1340×857× 1550 |

2205×2934 ×2190 |

Hot Sales

These are all our hottest products.

Both the quality and the price are highly appraised by customers.

Company Information

Aotian Machinery Manufacturing Co., Ltd. was founded in 1985, according to the modern enterprise mechanism into a large-scale standardized joint-stock enterprises, with 278 workers,including 23 engineers and technicians,15 senior engineers.In general, CHINAMFG is in the leading place of paper-making industry in China .

We will provide whole services according to our clients’ demand, like technical design, equipment production, installation and test instruction and so on. We will meet and exceed your expectations. Please contact our custom service for details.

Our Customer

These are our clients in Iran ,Pakistan and India.

Our products are sold to more than 100 countries all over the world.

Package & Shipping

Packaging

products will packaged according to their shapes, weight, transport distance and transport modes.Large machines will be packaged in sections.every part export machinery will be in standard export package seaworthy wooden case waterproof film, straw rope, carton box etc

Shipping

sea transportation is from HangZhou seaports or other china main ports.

the delivery time is decided by machine types.But we also try to make it follows your needs.

Customer Feedback

Our Products have sold to many countries,and won customer’s good reputation.

Our Service

Service first

1.To provide you with the transformation and upgrading of plant equipment programs, in order to improve the yield and quality

2.Always online to answer technical questions

3.The customer arrives China, accompanied this translation facility until send customers back

4.send engineers to the customer’s national installation and commissioning of the machine, to ensure the normal operation of the machine

5.Our products can guarantee excellent quality, if there is any quality problems, we flew to your country for your free service

FAQ

1.Q:Are you a manufacture?

A: Yes,we have been in providing the professional products in this field for 30 years.

2.Q:How to install the machine?

A:we can help with the installation by vedio,email,picture.if it is a large project,we can arrange our worker help you to install it in your country.

3.Q:How do you pack the products?

A:Normally as the export standard packaging or as your requirement.

4.Q:What’s your available port of shipment?

A:HangZhou port,ZheJiang port and so on.

5.Q:Is it customized available?

A:Yes,according to your detailed drawing you provided.

Contact Us

As most paper machinery products, pulping equipments, roll products need to be customized, the prices and sample prices shown on our product details page are for reference only, please contact our professional customer service and tell us your specifications and sizes, you will get a more reasonable and exciting price!

| After-sales Service: | 6 Month |

|---|---|

| Warranty: | 6 Month |

| Certification: | RoHS, ISO 9001:2000 |

| Samples: |

US$ 5000/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How Are Vacuum Pumps Employed in the Production of Electronic Components?

Vacuum pumps play a crucial role in the production of electronic components. Here’s a detailed explanation:

The production of electronic components often requires controlled environments with low or no atmospheric pressure. Vacuum pumps are employed in various stages of the production process to create and maintain these vacuum conditions. Here are some key ways in which vacuum pumps are used in the production of electronic components:

1. Deposition Processes: Vacuum pumps are extensively used in deposition processes, such as physical vapor deposition (PVD) and chemical vapor deposition (CVD), which are commonly employed for thin film deposition on electronic components. These processes involve the deposition of materials onto substrates in a vacuum chamber. Vacuum pumps help create and maintain the necessary vacuum conditions required for precise and controlled deposition of the thin films.

2. Etching and Cleaning: Etching and cleaning processes are essential in the fabrication of electronic components. Vacuum pumps are used to create a vacuum environment in etching and cleaning chambers, where reactive gases or plasmas are employed to remove unwanted materials or residues from the surfaces of the components. The vacuum pumps help evacuate the chamber and ensure the efficient removal of byproducts and waste gases.

3. Drying and Bake-out: Vacuum pumps are utilized in the drying and bake-out processes of electronic components. After wet processes, such as cleaning or wet etching, components need to be dried thoroughly. Vacuum pumps help create a vacuum environment that facilitates the removal of moisture or solvents from the components, ensuring their dryness before subsequent processing steps. Additionally, vacuum bake-out is employed to remove moisture or other contaminants trapped within the components’ materials or structures, enhancing their reliability and performance.

4. Encapsulation and Packaging: Vacuum pumps are involved in the encapsulation and packaging stages of electronic component production. These processes often require the use of vacuum-sealed packaging to protect the components from environmental factors such as moisture, dust, or oxidation. Vacuum pumps assist in evacuating the packaging materials, creating a vacuum-sealed environment that helps maintain the integrity and longevity of the electronic components.

5. Testing and Quality Control: Vacuum pumps are utilized in testing and quality control processes for electronic components. Some types of testing, such as hermeticity testing, require the creation of a vacuum environment for evaluating the sealing integrity of electronic packages. Vacuum pumps help evacuate the testing chambers, ensuring accurate and reliable test results.

6. Soldering and Brazing: Vacuum pumps play a role in soldering and brazing processes for joining electronic components and assemblies. Vacuum soldering is a technique used to achieve high-quality solder joints by removing air and reducing the risk of voids, flux residuals, or oxidation. Vacuum pumps assist in evacuating the soldering chambers, creating the required vacuum conditions for precise and reliable soldering or brazing.

7. Surface Treatment: Vacuum pumps are employed in surface treatment processes for electronic components. These processes include plasma cleaning, surface activation, or surface modification techniques. Vacuum pumps help create the necessary vacuum environment where plasma or reactive gases are used to treat the component surfaces, improving adhesion, promoting bonding, or altering surface properties.

It’s important to note that different types of vacuum pumps may be used in electronic component production, depending on the specific process requirements. Commonly used vacuum pump technologies include rotary vane pumps, turbo pumps, cryogenic pumps, and dry pumps.

In summary, vacuum pumps are essential in the production of electronic components, facilitating deposition processes, etching and cleaning operations, drying and bake-out stages, encapsulation and packaging, testing and quality control, soldering and brazing, as well as surface treatment. They enable the creation and maintenance of controlled vacuum environments, ensuring precise and reliable manufacturing processes for electronic components.

How Do Vacuum Pumps Contribute to Energy Savings?

Vacuum pumps play a significant role in energy savings in various industries and applications. Here’s a detailed explanation:

Vacuum pumps contribute to energy savings through several mechanisms and efficiencies. Some of the key ways in which vacuum pumps help conserve energy are:

1. Improved Process Efficiency: Vacuum pumps are often used to remove gases and create low-pressure or vacuum conditions in industrial processes. By reducing the pressure, vacuum pumps enable the removal of unwanted gases or vapors, improving the efficiency of the process. For example, in distillation or evaporation processes, vacuum pumps help lower the boiling points of liquids, allowing them to evaporate or distill at lower temperatures. This results in energy savings as less heat is required to achieve the desired separation or concentration.

2. Reduced Energy Consumption: Vacuum pumps are designed to operate efficiently and consume less energy compared to other types of equipment that perform similar functions. Modern vacuum pump designs incorporate advanced technologies, such as variable speed drives, energy-efficient motors, and optimized control systems. These features allow vacuum pumps to adjust their operation based on demand, reducing energy consumption during periods of lower process requirements. By consuming less energy, vacuum pumps contribute to overall energy savings in industrial operations.

3. Leak Detection and Reduction: Vacuum pumps are often used in leak detection processes to identify and locate leaks in systems or equipment. By creating a vacuum or low-pressure environment, vacuum pumps can assess the integrity of a system and identify any sources of leakage. Detecting and repairing leaks promptly helps prevent energy wastage associated with the loss of pressurized fluids or gases. By addressing leaks, vacuum pumps assist in reducing energy losses and improving the overall energy efficiency of the system.

4. Energy Recovery Systems: In some applications, vacuum pumps can be integrated into energy recovery systems. For instance, in certain manufacturing processes, the exhaust gases from vacuum pumps may contain heat or have the potential for energy recovery. By utilizing heat exchangers or other heat recovery systems, the thermal energy from the exhaust gases can be captured and reused to preheat incoming fluids or provide heat to other parts of the process. This energy recovery approach further enhances the overall energy efficiency by utilizing waste heat that would otherwise be lost.

5. System Optimization and Control: Vacuum pumps are often integrated into centralized vacuum systems that serve multiple processes or equipment. These systems allow for better control, monitoring, and optimization of the vacuum generation and distribution. By centralizing the vacuum production and employing intelligent control strategies, energy consumption can be optimized based on the specific process requirements. This ensures that vacuum pumps operate at the most efficient levels, resulting in energy savings.

6. Maintenance and Service: Proper maintenance and regular servicing of vacuum pumps are essential for their optimal performance and energy efficiency. Routine maintenance includes tasks such as cleaning, lubrication, and inspection of pump components. Well-maintained pumps operate more efficiently, reducing energy consumption. Additionally, prompt repair of any faulty parts or addressing performance issues helps maintain the pump’s efficiency and prevents energy waste.

In summary, vacuum pumps contribute to energy savings through improved process efficiency, reduced energy consumption, leak detection and reduction, integration with energy recovery systems, system optimization and control, as well as proper maintenance and service. By utilizing vacuum pumps efficiently and effectively, industries can minimize energy waste, optimize energy usage, and achieve significant energy savings in various applications and processes.

What Are the Primary Applications of Vacuum Pumps?

Vacuum pumps have a wide range of applications across various industries. Here’s a detailed explanation:

1. Industrial Processes:

Vacuum pumps play a vital role in numerous industrial processes, including:

– Vacuum Distillation: Vacuum pumps are used in distillation processes to lower the boiling points of substances, enabling separation and purification of various chemicals and compounds.

– Vacuum Drying: Vacuum pumps aid in drying processes by creating a low-pressure environment, which accelerates moisture removal from materials without excessive heat.

– Vacuum Packaging: Vacuum pumps are used in the food industry to remove air from packaging containers, prolonging the shelf life of perishable goods by reducing oxygen exposure.

– Vacuum Filtration: Filtration processes can benefit from vacuum pumps to enhance filtration rates by applying suction, facilitating faster separation of solids and liquids.

2. Laboratory and Research:

Vacuum pumps are extensively used in laboratories and research facilities for various applications:

– Vacuum Chambers: Vacuum pumps create controlled low-pressure environments within chambers for conducting experiments, testing materials, or simulating specific conditions.

– Mass Spectrometry: Mass spectrometers often utilize vacuum pumps to create the necessary vacuum conditions for ionization and analysis of samples.

– Freeze Drying: Vacuum pumps enable freeze-drying processes, where samples are frozen and then subjected to a vacuum, allowing the frozen water to sublimate directly from solid to vapor state.

– Electron Microscopy: Vacuum pumps are essential for electron microscopy techniques, providing the necessary vacuum environment for high-resolution imaging of samples.

3. Semiconductor and Electronics Industries:

High vacuum pumps are critical in the semiconductor and electronics industries for manufacturing and testing processes:

– Semiconductor Fabrication: Vacuum pumps are used in various stages of chip manufacturing, including deposition, etching, and ion implantation processes.

– Thin Film Deposition: Vacuum pumps create the required vacuum conditions for depositing thin films of materials onto substrates, as done in the production of solar panels, optical coatings, and electronic components.

– Leak Detection: Vacuum pumps are utilized in leak testing applications to detect and locate leaks in electronic components, systems, or pipelines.

4. Medical and Healthcare:

Vacuum pumps have several applications in the medical and healthcare sectors:

– Vacuum Assisted Wound Closure: Vacuum pumps are used in negative pressure wound therapy (NPWT), where they create a controlled vacuum environment to promote wound healing and removal of excess fluids.

– Laboratory Equipment: Vacuum pumps are essential in medical and scientific equipment such as vacuum ovens, freeze dryers, and centrifugal concentrators.

– Anesthesia and Medical Suction: Vacuum pumps are utilized in anesthesia machines and medical suction devices to create suction and remove fluids or gases from the patient’s body.

5. HVAC and Refrigeration:

Vacuum pumps are employed in the HVAC (Heating, Ventilation, and Air Conditioning) and refrigeration industries:

– Refrigeration and Air Conditioning Systems: Vacuum pumps are used during system installation, maintenance, and repair to evacuate moisture and air from refrigeration and air conditioning systems, ensuring efficient operation.

– Vacuum Insulation Panels: Vacuum pumps are utilized in the manufacturing of vacuum insulation panels, which offer superior insulation properties for buildings and appliances.

6. Power Generation:

Vacuum pumps play a role in power generation applications:

– Steam Condenser Systems: Vacuum pumps are used in power plants to remove non-condensable gases from steam condenser systems, improving thermal efficiency.

– Gas Capture: Vacuum pumps are utilized to capture and remove gases, such as hydrogen or helium, in nuclear power plants, research reactors, or particle accelerators.

These are just a few examples of the primary applications of vacuum pumps. The versatility and wide range of vacuum pump types make them essential in numerous industries, contributing to various manufacturing processes, research endeavors, and technological advancements.

editor by CX 2023-12-03

China Professional High Vacuum Pump for Vacuum Wood Drying Kiln Dryer Machinery with Best Sales

Product Description

High Vacuum Pump For Vacuum Wood Drying Kiln Dryer Machinery

| Model | Weight | Frequency | Voltage | Current | Rated Output | Noise | Max Airflow |

| KG | Hz | V | A | KW | DB(A) | m³/h | |

| 2LG 571-7AH16 | 5 | 50 | 200-240 △/345-415Y |

1.26△/0.72Y | 0.2 | 46 | 55 |

| 60 | 220-275 △/380-480Y |

1.55△/0.9Y | 0.23 | 48 | 68 |

Blower Applications :

•Blowing and Suction

•Pneumatic conveying system

•Spa Facilities

•Vacuum lifting and clamping system

•Plating Equipment

•Packaging and printing equipment

•Filling Equipment

•Bag/bottle/hopper filling system

•Water/Sewage Treatment

•Soil improvement

•Aquaculture

•Foam molding system

•Pneumatic

•Food processing system

•Automation Technology

•Plastic and rubber industry

•Handling Technology

•Beverage industry

•Clamping Technology

•Timber industry

•Vacuum Work holding Technology

•Environmental engineering

•Electrical Component Manufacturer

•Electronics/semiconductor industry

•UV Flatbed Printer

•Pharmaceutical industry

•Large Format Printing

•Hospital and laboratory equipment

•CNC Equipment

•Textile Industry

•CNC Engraving Machine

•Car Wash Coin-operated Vacuum Systems

•CNC Cutting Machine

•Commercial Ducted Vacuum Systems

•CNC Laser Engraving Machine

•Industrial Ducted Vacuum Systems

•CNC Woodworking Machine

•Bio-medical Transfer Facilities

•Plasma Cutting Machine

•Dental Equipment

•Feeding Equipment

•Textile Industrial

Product Features:

1. Light weight high pressure big volume low noise.

2. Aluminum alloy material, greatly reduce weight, achieve the goal of lightweight.

3. high pressure, big air volume, low noise, long service life.

Our service:

Marketing Service

100% tested CE certified blowers.Special customized blowers(ATEX blower,belt-driven blower) for special industry.Like gas transportation,Medical industry…Professional advice for model selection and further market development.

After-sale Service

Experienced suggestion for blower installation and use.12 months warranty.Long-term technical support.

FAQ:

Q: Are you manufacturer?

A: Yes, we are manufacture.

Q: Do I get guarantee of products?

A: Yes, every product is 1 year quality warranty under customer correct using the products.

Q: How to buy 1 pcs to test quality?

A: Please contact us, we have our express agent can choosing the cheapest and fastest way to delivery.

Q: I only want to buy 10pcs, but express is too high cost, what can I do?

A: Please contact us and provide destination port details. We have own forwarder. Working term is very fexible in our company, FOB or C&F are no problem for us

Q: How can I pay to you?

A: We accept , T/T,L/C or you any other payment terms for your convenience.

| Usage: | for Manufacture |

|---|---|

| Certification: | RoHS |

| Frequency: | 50/60Hz |

| Voltage: | 200-480V |

| Model: | 2LG 010-7ah16 |

| Max Airflow: | 55/68m3/H |

| Customization: |

Available

|

|

|---|

Types of vacuum pumps

A vacuum pump is a device that draws gas molecules from a sealed volume and maintains a partial vacuum. Its job is to create a vacuum in a volume, usually one of several. There are several types of vacuum pumps, such as root pumps, diaphragm pumps, rotary piston pumps, and self-priming centrifugal pumps.

The diaphragm pump is a dry positive displacement vacuum pump

Diaphragm pumps are a versatile type of vacuum pump. They can be installed in a variety of scenarios including container emptying, positive suction, and simultaneous fluid mixing. Their performance depends on the stiffness and durability of the diaphragm, which in turn depends on the material.

They have good performance when running in dry mode. Diaphragm pumps work very similarly to the human heart, which is why they are often used to create artificial hearts. In addition, the diaphragm pump is self-priming and has high efficiency. They are also capable of handling the most viscous liquids and are used in almost all industries.

However, this type of pump has several disadvantages. One of them is that they are difficult to restart after a power outage. Another disadvantage is that they can generate a lot of heat. Fortunately, this heat is carried away by airflow. However, this heat builds up in the multistage pump. If this happens, the diaphragm or motor may be damaged. Diaphragm pumps operating in two or more stages should be fitted with solenoid valves to maintain vacuum stability.

Diaphragm pumps are a good choice for drying processes where hygiene is important. These pumps have check valves and rubber or Teflon diaphragms. Diaphragm pumps are also ideal for high viscosity applications where shear sensitivity is important.

Roots pumps are dry method centrifugal pumps

Roots pumps use a vane rotor pump with two counter-rotating vanes that move in opposite directions to move the gas. They are often the first choice for high-throughput process applications. Depending on the size and number of blades, they can withstand up to 10 Torr.

Centrifugal pumps have several advantages, including the ability to handle corrosive fluids and high temperatures. However, when choosing a pump, it is essential to choose a reputable manufacturer. These companies will be able to advise you on the best pump design for your needs and provide excellent after-sales support. Roots pumps can be used in a wide range of industrial applications including chemical, food, and biotechnology.

The Roots pump is a dry centrifugal pump whose geometry enables it to achieve high compression ratios. The screw rotors are synchronized by a set of timing gears that allow gas to pass in both directions and create a compressed state in the chamber. The pre-compressed gas is discharged through a pressure connection and cooled with water. Some pumps are also able to accept additional cooling gas, but this should be done with caution.

The size of the impeller plays an important role in determining the pump head. The impeller diameter determines how high the pump can lift the liquid. Impeller speed also affects the head. Since the head is proportional to the specific gravity of the liquid, the available suction pressure will be proportional to the density of the liquid. The density of water is about 1.2 kg/m3, and the suction pressure of the centrifugal pump is not enough to lift the water.

The rotary vane pump is a self-priming centrifugal pump